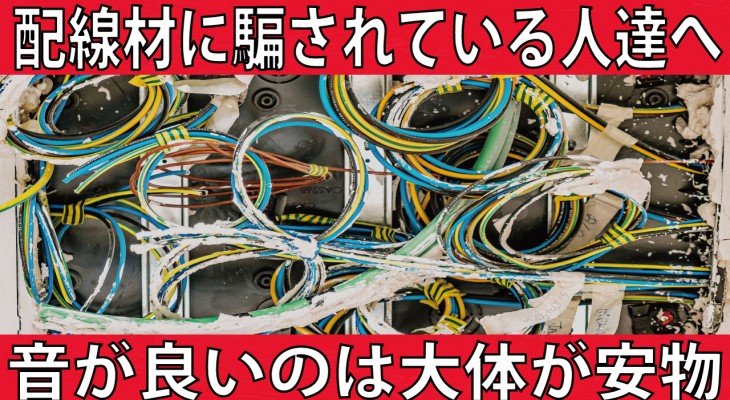

フェンダージャパン製ストラトキャスター、Eシリアル80年代製ST-65のフレットすり合わせです。

フレット消耗で音詰まりしている状態です。

近年は古い年代のフェンダージャパン製が非常に高額になりましたが、別にSVが特別良いと思いません。

結構2000年代半ば頃まで良い物が多いので、無理して古い年代を買う必要はありません。

ネック剛性が高く、弦を張っても全然反らないネックで材質がとても良さそうです。

指板が円錐指板の精度が高く、またシムも必要としない仕様で作りが良いです。

音が良く、現行のカスタムショップ製と大きな差が感じません。

当時はこれが数万円(型番の数値が値段)で売っていたので、むしろ昔の状況を知っているシニア世代が「楽器は値段じゃない・安い物でも良い物は多い」という意識になるはずなのですが、不思議と逆なのです。

昔のプレイヤー達も良い物がその辺で安く売られていた事に気が付かなかった様です。

ありがとうございました♪

This is a Fender Japan Stratocaster, E Serial 80’s ST-65 fretted.

It is sound clogged due to fret wear.

I don’t think SVs are particularly good.

There is no need to buy an older one, as there are many good ones until the mid-2000s.

The neck is very rigid and does not warp at all when strings are put on it, and the material seems to be very good.

The fingerboard is well made with a conical fingerboard with high precision and specifications that do not require shims.

The sound is good, and I don’t feel a big difference from the current Custom Shop models.

At that time, these were sold for several tens of thousands of yen (the number in the model number is the price), so the senior generation who know the old situation should rather be aware that “instruments are not about price, and many cheap ones are good,” but strangely enough, the opposite is true.

It seems that the players of the past were not aware of the fact that good ones were sold cheaply around here.

Thank you very much.

〒114-0014 東京都北区田端1-21-3 エーデルワイス101

ギターリペア工房 Draw a New Sound

東京都 山手線 田端から徒歩2分 どこよりも早いリペア早期仕上げ対応可能のリーズナブル料金&丁寧な作業のギターリペアショップです♪

●ホームページ Draw a New Sound

●YouTubeではブログでは語られない裏話からギターの作り方まで掲載中!

マイチャンネル YouTubeチャンネル

●ツイッター DNS_Guitar